Sikaflex®-265 weathering-resistant direct-glazing adhesive and sealant

parameter

| Chemical base | 1-component polyurethane |

| Color (CQP001-1) | Black |

| Cure mechanism | Moisture-curing |

| Density (uncured) | 1.3 kg/l |

| Application temperature | 10 ─ 35 °C |

| Skin time (CQP019-1) | 45 minutes |

| Shore A hardness (CQP023-1 / ISO 7619-1) | 45 |

| Tensile strength (CQP036-1 / ISO 527) | 6 MPa |

| Elongation at break (CQP036-1 / ISO 37) | 450 % |

| Service Temperature CQP509-1 / CQP513-1) | -40 ─ 90 °C |

PRODUCT BENEFITS

▪ Suitable for bonding and sealing

▪ Passes EN45545-2 R1/R7 HL3

▪ Good weathering resistance

▪ Solvent-free

▪ Low odor

Excellent processing and tooling characteristics

AREAS OF APPLICATION

Sikaflex®-265 is designed for direct glazing applications in both the OEM and repair markets. Owing to its good tooling properties and enhanced weathering stabilization, the product may be used for exterior joints.

Seek manufacturer’s advice and perform tests on original substrates before using Sikaflex®-265 on materials prone to stress cracking.

Sikaflex®-265 is suitable for experienced professional users only. Test with actual substrates and conditions have to be performed to ensure adhesion and material compatibility.

CURE MECHANISM

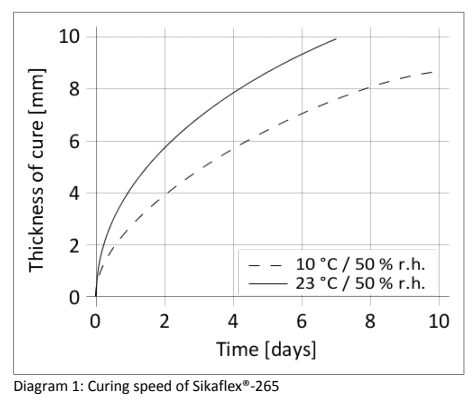

Sikaflex®-265 cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds somewhat slower.

CHEMICAL RESISTANCE

Sikaflex®-265 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated miner