Sikaflex221 Single component adhesive sealant

Product technical data

| Colour | White, gray, black, brown |

| Curing mechanism | Moisture cure |

| Density (uncured) | About 1.3 kg/l |

| Sag resistance | Good |

| Construction temperature | 5 - 40°C |

| Shore A hardness (CQP 023-1/ISO 868) | 40 |

| Tensile strength (CQP 036-1/ISO 37) | 1.8 N/mm2 |

| Tear strength (CQP 045-1/ISO 34) | 7 N/mm |

| Operation temperature | -40 - 90°C |

| Shelf life (sealed storage below 25 ° C) (CQP 016-1) | 12 months |

Applicable scope

Sikaflex ®- 221 has good adhesion to many substrates. It is suitable for permanent elastic seals that require high adhesive strength. Applicable substrates include wood, metal, metal primer, and topcoat (double

Component systems), ceramic materials and plastics. If used in colored or transparent materials that are prone to cracking under stress

Please seek the manufacturer's opinion on the substrate. This product is only for users with professional skills to use. In order to ensure the bonding effect and compatibility between the product and materials, tests should be conducted in advance on the actual substrate and environment.

Curing mechanism

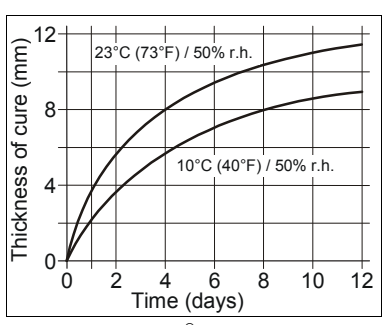

Sikaflex ®- 221 reacts and solidifies with moisture in the atmosphere. Usually, the lower the temperature, the more

The lower the moisture content, the slower the reaction process to some extent. (As shown in the figure)

Chemical resistance

Sikaflex ®- 221 is resistant to fresh water, seawater, lime water, sewage, dilute acid and alkali solutions; Transient endurance

Fuel oil, mineral oil, vegetable oil, animal fat, and crude oil; Not resistant to organic acids, alcohol, concentrated

Inorganic acids, corrosive solutions or solvents. The above instructions are only for general guidance. For specific construction projects, if needed, we will provide suggestions.

Packaging Information

| Tubing | 310 ml |

| Sausage pack | Sausage pack |

| Small bucket | 23l |

| Large barrel | 195l |