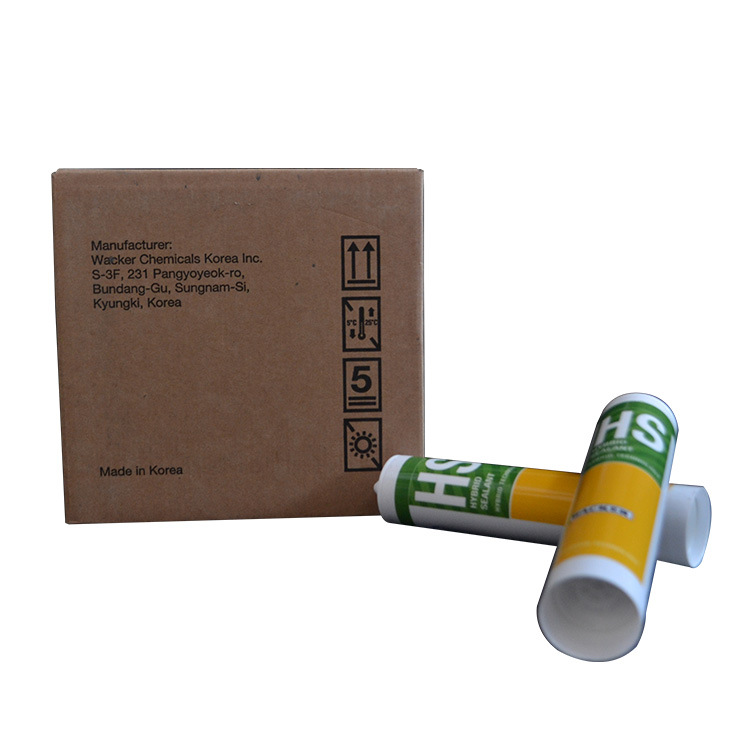

WACKER ® HS – HYBRID SEALANT

Features &Benefits

1. almost odorless

2. solvent-free

3. isocyanate free

4. phthalate free

5. easy to process from +5 °C to +40 °C

7. stable at temperatures from -40 °C to +80 °C

8. tack-free and highly elastic after curing

9. non-corrosive

10. paintable

Applications

1. For connection joints that are subsequently painted - For fixation where flexibility of the sealant is still required

2. For sealing joints between a wide variety of materials, such as wood, glass, metals, plastics or mineralbased substrates

3. For stress-relieving bonding and fixation Adhesion WACKER ® HS - HYBRID SEALANT exhibits excellent primerless adhesion to a wide variety of materials such as wood, glass, metals, plastics or mineral-based substrates. Users must carry out own tests due to the great variety of substrates.

Technical data

| Property | Condition | Value | Method |

| Density | 23 °C | 1.4 g/cm³ | ISO 1183-1 A |

| Consistency | - | non-sag | ISO 7390, profile U 20 |

| Skin formation time | - | approx. 20 - 40 min | internal method |

| These figures are only intended as a guide and should not be used in preparing specifications. | |||

| Modulus at 100 % | 0.85 N/mm² | ISO 37 | |

| elongation (S2-dumbbell) | - | ||

| Modulus at 100 % | 0.7 N/mm² | ISO 8339 | |

| elongation (joint) | - | ||

| Hardness Shore A | - | 35 | ISO 868 |

| Tensile strength (S2- | 2.3 N/mm² | ||

| dumbbell) | - | - | |

| Tensile strength (joint) | - | 2.2 N/mm² | - |

| Ultimate elongation (S2- | 5.2 | ||

| dumbbell) | - | - | |

| Ultimate elongation (joint) | - | 6 | - |

| These figures are only intended as a guide and should not be used in preparing specifications. | |||

How to Use

Processing

The substrate areas that will be in contact with the sealant must be clean, dry and free of all loose material such as dust, dirt, rust, oil and other contaminants. Non-porous substrates should be cleaned with a solvent and clean, lint-free, cotton cloth. Remove residual solvent before it evaporates with a fresh clean, dry cloth. For application from cartridges cut thread open, fix nozzle on top and cut to required bead size. The sealant can be applied in beads or layers. It requires moisture in order to cure. The curing time can take longer at lower temperatures, lower humidity or by low volume of air exchange. It is the responsibility of the user to test the compatibility of the sealant with the adjoining materials. Incompatible substances like coatings or organic plasticizers can lead to discoloration of the sealant. Cleaning agents and gaseous emissions can damage the sealant in its function or change its appearance. WACKER cannot make a general statement to the compatibility of all these varying materials with the sealant. In case of doubt the user shall conduct appropriate preliminary tests.

Usable Life and Storage

The 'Best use before end' date of each batch is shown on the product label. Storage beyond the date specified on the label does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons. Store dry and cool.

Limitations

This product is neither tested nor represented as suitable for medical or pharmaceutical uses.